印刷电子是近年来兴起的一种先进电子制造技术,其原理在于利用传统的丝印、喷墨等印刷手段将导电、介电或半导体性质的材料转移到基板上,从而制造出电子器件与系统[1,2]。与传统的减材式电子制造方法相比,印刷电子技术在大面积、低成本、个性化、柔性化、低能耗、绿色环保等方面具有明显优势。此类增材电子制造技术中所采用的导电墨水主要由导电填料、连结料、添加剂及溶剂等组成[3]。印刷电子技术所采用的基底可以是塑料、金属、玻璃、纺织品、陶瓷或纸张等。传统印刷方法根据印版的特点主要分为四类:(1)凸版印刷(letterpress printing);(2)凹版印刷(gravure printing);(3)平版印刷(lithographic printing);(4)孔版印刷(丝网印刷,screen printing)[4]。将传统的印刷方式与现代机械电子技术相结合,便产生了激光打印、喷墨打印等印刷方式。由于具备节能、快速、污染小等特点,印刷电子技术在低成本制造太阳能电池、柔性显示器件、电子标签以及智能包装方面已展示出巨大的应用潜力[3]。

制约印刷电子技术发展的一个关键因素在于导电墨水材料的获取。近年来,液态金属电子打印技术的出现,促成了新的研究与应用。为此,本文在简要回顾传统的印刷电子导电墨水的基础上,重点评述了液态金属这一新型电子墨水的研究进展。

1 印刷电子技术中的传统导电墨水传统导电墨水按照功能组分的不同,可以分为碳系导电墨水、高分子导电墨水和金属导电墨水三大类[5]。

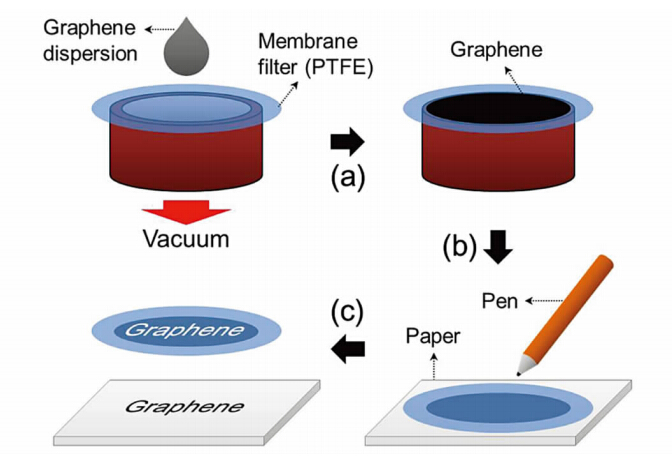

碳系导电墨水的导电功能组分通常包括碳纳米管、石墨烯及富勒烯等材料。以石墨烯为例,Hyun等[6]阐明了采用石墨烯分散液为墨水制作可折叠式电子线路的方法(如图1所示)。基本步骤是:首先,使用一个疏水性聚四氟乙烯(polytetrafluoroethylene,PTFE)薄膜滤器(孔径:0.2 μm)对石墨烯分散液进行真空过滤,石墨烯纳米片由此会均匀地沉积在薄膜滤器上。之后,再将薄膜滤器翻转并放置于纸基底上,使有石墨烯的一面接触纸面,用笔在薄膜滤器的背面勾画电路 线图,然后将薄膜滤器从纸基底上移走。这样,即可将石墨烯电路印刷在纸基底上。

| 图1 通过真空过滤方法在纸基底上制备石墨烯电路 (a)用聚四氟乙烯薄膜滤器过滤石墨烯分散液;(b)将薄膜滤器翻转并置于纸上, 然后用笔在薄膜滤器的背面勾画出电路;(c)将薄膜滤器从纸基底上移除,即形成目标组件[6] Making graphene circuit on paper substrate via vacuum filtration method (a) The graphene dispersion is filtered by a PTFE membrane,(b) The membrane filter is turned over and put on a paper,and a circuit is drawn on the back of the membrane filter with a pen,(c) The membrane filter is removed from the paper substrate and the target is formed[6] |

导电高分子墨水包括聚(3,4-乙烯二氧噻吩)-聚苯乙烯磺酸(PEDOT/PSS)、聚苯胺、聚噻吩、聚吡咯等,可以采用直写式[7](direct writing)、蘸笔纳米光刻法[8,9](dip-pen nanolithography)、电子束光刻法[10](e-beam nanolithography)、喷墨打印[11,12](inkjet printing)等方法进行印制。

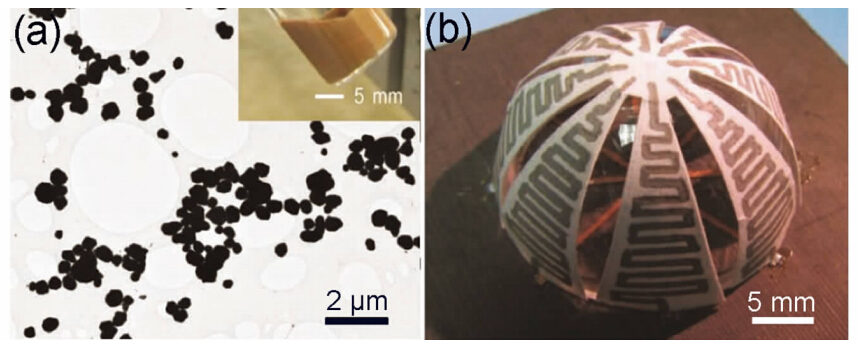

典型的金属导电墨水包括金属纳米颗粒(包括金,银,铜等)分散液或导电金属前驱体化合物溶液。Russo等[13]介绍了一种制作纸基柔性电子电路的方法,以银纳米颗粒溶液为墨水,通过笔直接书写在纸上,具有方便快捷的特点。图2(a)显示了这种墨水的实物图及墨水中银粒子的TEM(transmission electron microscope)图像,由该墨水制作的3D天线如图2(b)所示,制作过程是:首先用笔在粘性纸上勾画出导电银线,然后将粘性纸粘附在半球状中空玻璃基底上,最后将要制作的天线电路进行热处理(加热到550 ℃后退火)。处理过的打印银线其电阻率可以达到1.6×10-6 Ω·cm。

| 图2 (a)合成墨水中银粒子的TEM图像,插图为墨水的实物图;(b)打印的3D天线的实物图[13] (a) TEM image of the synthesized silver particles,the inset is the real photo of the ink;(b) The real photo of the printed 3D antenna [13] |

液态金属是新近出现的一大类导电墨水,Zhang等[14]首次系统的阐述了液态金属墨水的种类和应用,并将这类电子制造方法命名为“DREAM ink”(Direct writing of electronics based on alloy and metal ink)。

液态金属通常指的是熔点低于200 ℃的低熔点合金,其中室温液态金属的熔点更低,在室温下即呈液态。与传统流体相比,液态金属具有优异的导热和导电性能,且液相温度区间宽广,因此日益得到越来越多的研究。自然界存在的室温液态纯金属有汞、铯、钫和镓,熔点分别是-38.87 ℃、28.65 ℃、27 ℃和29.8 ℃,其中汞的挥发性比较大,并且汞和汞合金(汞齐,Amalgam)具有一定的毒性,含汞残余物进入生态循环,会对人类和环境造成危害[15,16,17],因此应当谨慎使用。铯和钫属于性质活泼的碱金属,铯在空气中极易被氧化,和水会发生剧烈反应,而钫则是一种不稳定的放射性元素。目前,熔点低于室温的镓基合金是使用最多的导电墨水。表1列出了几种液态金属和水的物理性质对比,其中,EGaIn为共晶镓铟合金Ga75.5In24.5(其中Ga和In的质量分数分别为75.5%和24.5%),Galinstan为共晶镓铟锡合金Ga62.5In21.5Sn16(其中Ga、In和Sn的质量分数分别为62.5%、21.5%和16%)。

| 表1 几种典型液态金属和水的物理性质比较 A comparison of the physical properties between several typical liquid metals and water |

传统的导电墨水,不论是导电高分子系、纳米金属、有机金属导电墨水,或者是碳材料类导电墨水,自身均不具备导电性,在打印后需要经过一定的后处理工艺(如烧结、退火),将导电墨水中的溶剂、分散剂、稳定剂等去除,使导电材料形成连续的薄膜后,才具备导电性[27]。不论是墨水的配制,还是后处理工艺,都较为复杂。除此之外,采用纳米金、银墨水进行大面积打印使用时成本较高,而纳米铜粒子容易氧化。与传统导电墨水相比,液态金属墨水材料的配制则相对简单,在打印后无需进行后处理即具备导电性,而且电导率相对较高,是一种较为理想的导电墨水。表2比较了液态金属与几种传统导电墨水的电导率。

| 表2 几种典型导电墨水电导率的比较 A comparison of the electrical conductivities of several typical conductive inks |

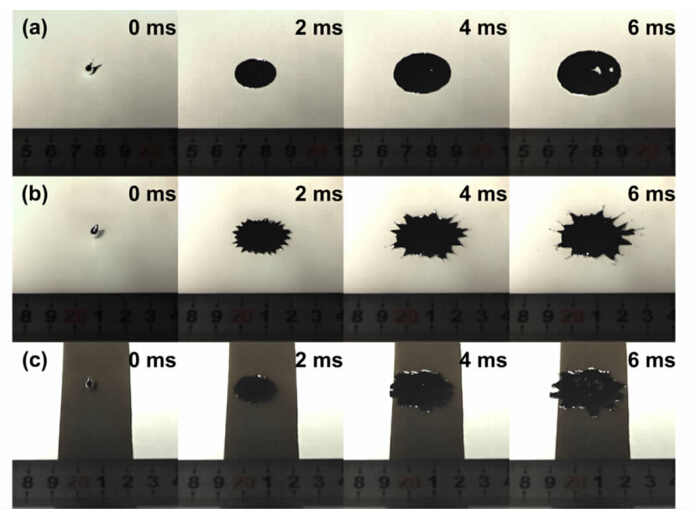

当前,最具代表性的室温液态金属墨水为镓及镓基合金。当镓暴露于空气中时,很容易与氧气反应生成镓氧化物。然而,生成的氧化物会阻止内部纯镓的进一步氧化,从而起到保护作用,这一点类似于铝[33]。与镓相比,铟不易被氧化[34],因此在由镓和铟所形成的共晶镓铟合金(EGaIn)中,包覆在合金外表面的主要是镓的氧化物。镓氧化物的存在改变了共晶镓铟合金的物理性质,例如纯EGaIn液滴的表面张力约为435 mN/m,而包覆氧化物薄膜的EGaIn液滴的表面张力约为624 mN/m,表面张力的增大使得EGaIn可以形成较大的液滴。同时,镓氧化膜也改变了EGaIn液滴的机械性能,使得EGaIn液滴类似于一个具有弹性的固体,当表面应力超过0.5 N/m时,液滴才表现出液体的流动性。我们[35]研究了液态金属EGaIn墨水与不同基底的碰撞特性,相比纯EGaIn,氧化后的EGaIn墨水与基底之间有更好的粘附性。此外,EGaIn墨水与不同基底的粘附性也不相同,图3显示了部分氧化后的EGaIn墨水在三类基底材料(打印纸、硅胶板和橡胶板)上的碰撞行为[35]。基底不同,液态金属的碰撞特性不同,利用这一特点可筛选彼此匹配的液态金属墨水与打印基底。更多的直写式电子电路与器件研究[36, 37]也表明,液态金属的氧化工艺是调控此类墨水与特定基底材料粘附性的重要手段。

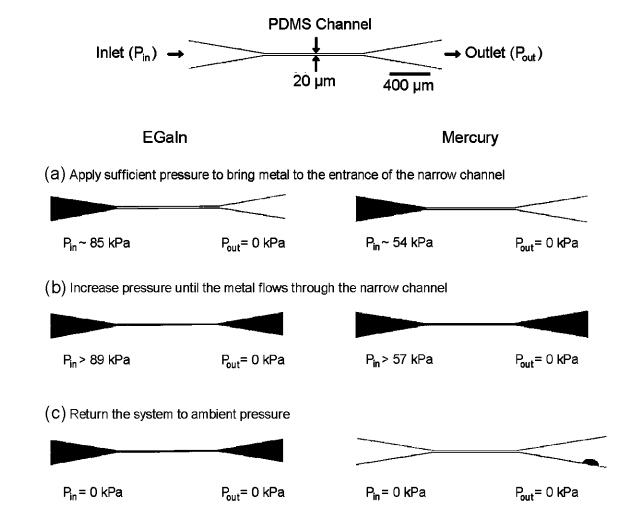

为了研究在管道中充填液态金属以形成特定导线的问题,研究人员[22]对比考察了EGaIn液滴和Hg液滴在PDMS微流道中的行为,所设计的实验如图4所示。当入口压强足够高时,EGaIn和Hg均能迅速充满微流道。当入口压强减小至0 kPa时,EGaIn仍保持填充微流道的状态不变,而Hg却从微流道中迅速排出。如果事先在流道 中注入10%(质量分数)的HCl水溶液,以除去所充入的EGaIn表面的氧化膜,则EGaIn在微流道中的行为类似于Hg,这说明表面氧化膜对于充填于微流道中的EGaIn起到了稳定结构的作用,由此可形成相应的管道填充型液态金属电路构件。

| 图3 EGaIn墨水在三种不同基底材料上的碰撞行为,基底为:(a)打印纸;(b)硅胶板;(c)橡胶板[35] Impacting behaviors of EGaIn ink on three different substrates: (a) printing paper,(b) silicon gel plate,(c) rubber plate[35] |

| 图4 EGaIn和Hg在PDMS微流道中的黏附行为比较 (a)两种金属均充填至微流道入口;(b)当入口压强超过临界值时,两种金属迅速充满流道;(c)当入口压强减至0 kPa时,EGaIn保持填充状态,而Hg则迅速从微流道中排出[22] A comparative study on adhesion behaviors of EGaIn and Hg in microchannels made of PDMS (a) both metals were filled to the inlet of channels,(b) when the inlet pressure became high enough,both metals were rapidly filled the channels,(c) when the inlet pressure was reduced to 0 kPa,EGaIn maintained its filled state,whereas Hg rapidly withdrew from the channel[22] |

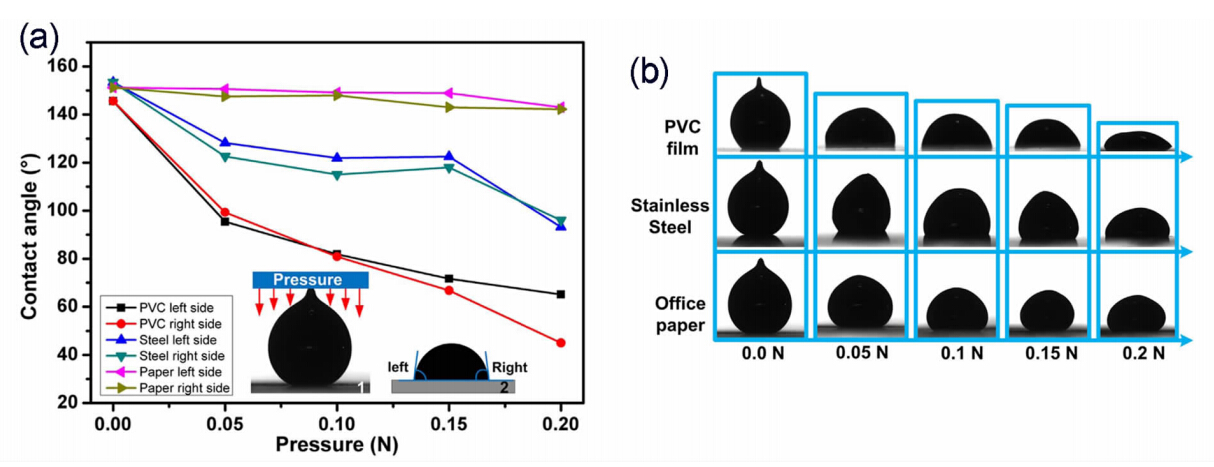

Gao等[38]研究了氧化程度对液态金属润湿性和电导率的影响,采用的金属为GaIn10(其中Ga和In的质量分数分别为90%和10%),基底有环氧树脂板、玻璃、塑料、硅胶板、纸、布及玻璃纤维等。实验发现,随着液态金属中氧化物含量的增加,其对不同基底的润湿性会逐渐改善,但电导率降低。Zheng等[39]研究了在不同外加压力下,EGaIn液滴在3种基底(PVC(polyvinyl chloride)薄膜、不锈钢、办公用纸)上的接触角,测量结果如图5所示。从图中看出,随着外加压力的增大,EGaIn液滴在PVC薄膜上的接触角下降最大,当外加压力为0.1 N时,接触角小于90°。总体而言,EGaIn液滴对PVC薄膜的润湿性最好,因此,PVC薄膜适合于作为EGaIn导电墨水的印刷基底材料。

基底表面粗糙度与液态金属液滴润湿性的关系也是应用中的关键问题,Kramer等[40]研究了EGaIn和Galinstan液滴在不同粗糙度的Si、In、Sn薄膜上的润湿性,实验结果显示,薄膜表面的粗糙度对液滴的润湿性有至关重要的影响。

| 图5 (a)EGaIn液滴分别在PVC薄膜、不锈钢、办公用纸上的接触角,并随外加压力增加(从0 N增加到0.2 N)的变化趋势, 插图是外加压力示意图和接触角示意图;(b)不同外加压力下,EGaIn液滴对这3种基底的润湿效果[39] (a) The measured contact angles of EGaIn droplets on PVC plastic film,stainless steel,office paper,respectively,as a function of impressed external minute-pressures increasing from 0 to 0.2 N. The inset pictures present the schematic of the impressed pressure and the illustration of the contact angle,(b) the wetting effect of EGaIn droplets on these three kinds of substrate under different external pressures[39] |

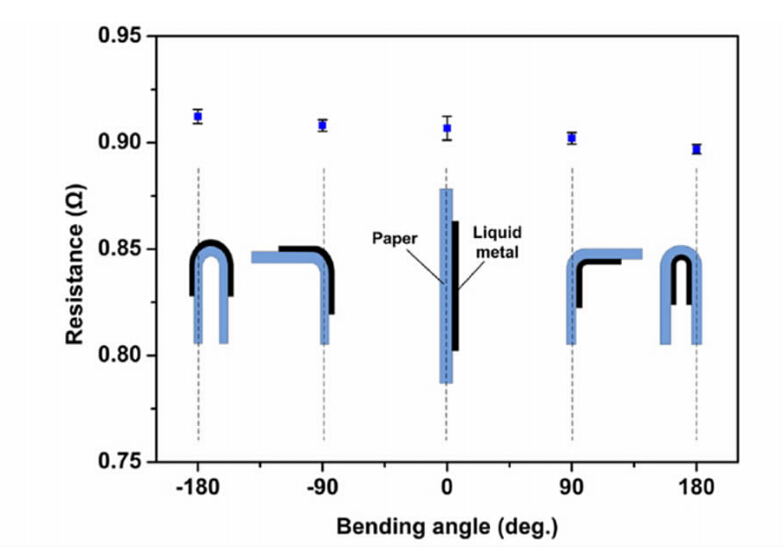

在制作柔性电子线路时,一般要求基底有一定的可弯折性。为此,Zheng等[41]研究了打印在柔性基底上导线的电学可靠性,液态金属墨水采用EGaIn,导线打印在铜版纸上,其长和宽分别为18 cm和1 mm,然后将导线用室温硫化硅橡胶(room temperature vulcanizing silicone rubber)封装。测量结果显示在图6中。可以看出,在弯折角度分别为-180°、-90°、0°、90°、180°时,导线的电阻率几乎没有变化,说明液态金属电路具有良好的电学稳定性。

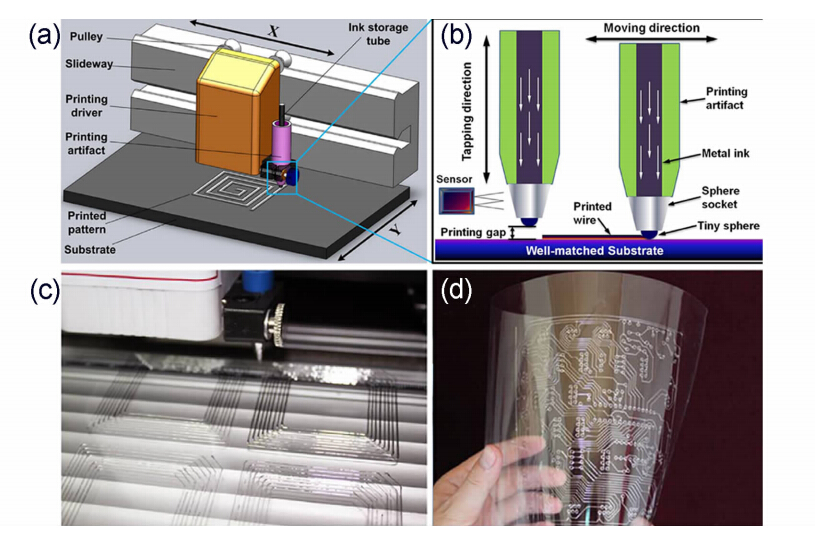

4 液态金属打印方法由于表面张力高、密度大,液态金属打印有其特殊性。为此,Zheng等[39]提出轻敲式(tapping mode)电子打印的概念,其打印机结构原理如图7(a)所示,其中,储墨笔筒(ink storage tube)固定 在打印驱动器(printing driver)上,驱动器通过滑

| 图6 五种弯折角度下打印导线(长、宽各为18 cm和1 mm)的电阻值[41] Resistance values of a printing wire with length of 18 cm and width of 1 mm respectively at five different bending angles [41] |

| 图7 (a)液态金属打印机结构原理图;(b)打印头工作原理;(c)在PVC塑料基底上的打印过程;(d)打印出的PCB电路[39] (a) The structure diagram of a liquid metal printer; (b) the scheme of the printing head; (c) the printing process on the PVC substrate; (d) the printed PCB circuit[39] |

轮(pulley)夹持于导轨(slideway)上,进而使打印头可以沿着导轨在X方向自由运动,基底(substrate)板通过电机驱动沿Y方向移动。因此可以使得打印头定位在基底板控制区域中的任意位置。打印头结构如图7(b)所示,笔头的轻敲模式指的是笔头可以在Z方向做小距离的移动。开始打印的时候,打印头下落接触基底,打印结束则上抬一个高度(printing gap),以免打印头破坏已经打印好的线条。在打印的过程中,打印头球珠由于与基底的摩擦力相互作用而转动,由此使笔筒中的液态金属墨水流下。打印头工作时的图像如图7(c)所示。运用这种方法,可以低成本制作PCB (printed-circuit-on-board)电路、天线等图案。图7(d)是一幅打印出的PCB电路图。

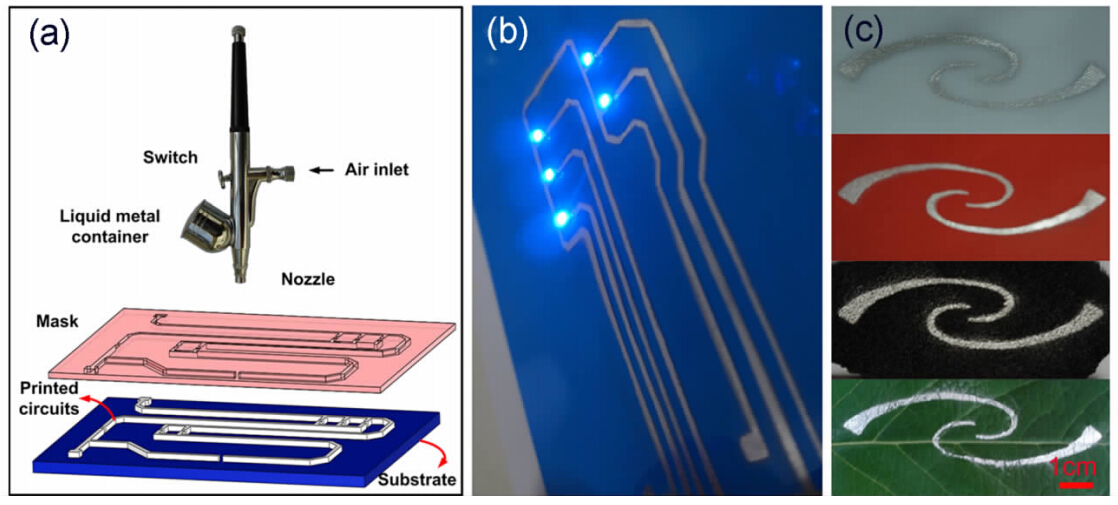

与上述的接触式打印方法不同,Zhang等[42]提出另一种可在任意表面制造电路的非接触式打印方法——雾化喷墨式液态金属打印,使用的打印墨水为EGaIn,打印原理如图8(a)所示。装置由喷笔(airbrush)、掩膜板(mask)、基底(substrate)组成,液态金属墨水由容器腔(liquid metal container)中流入喷笔,在喷嘴(nozzle)处被通入 的高压气体吹散成气雾状,最终液态金属微液滴

| 图8 (a)雾化喷墨式液态金属打印原理图;(b)打印的LED电路图; (c)基底(从上到下依次是:聚氯乙烯、打印纸、多孔橡胶及树叶)表面的打印线[42] (a) The schematic diagram of the atomized spraying of liquid metal,(b) the printed LED circuit,(c) conductive tracks on the surfaces of the substrates which are polyvinylchloride,typing paper,porous rubber and tree leaf,from top to bottom,respectively [42] |

通过掩膜板而喷涂在基底表面,喷涂的形状由掩膜板的空隙形状决定。由雾化喷墨式液态金属打印法打印的LED电路图如图8(b)所示,这一技术甚至使得树叶、粗燥的橡胶等基底也可变身电路板(图8(c))。

此外,其它液态金属印刷方法还包括直接书写式液态金属打印法[41]、微接触式液态金属打印法[43]、掩膜沉积法[44]等。以微接触式打印法为例,其打印过程是:首先将弹性打印头移到液态金属池的上方并浸入,随后将蘸上液态金属液滴的打印头移到基底上方并压印,由此就完成了一个点的打印,重复这样的过程并使压印点排列成图形,即实现液态金属的打印。

5 展望总的说来,印刷电子技术是当前备受关注的前沿热点,在消费电子、能源、医疗等方面具有巨大的发展潜力,影响其发展的因素主要是墨水种类的限制。因而,研制具有优良物理化学性质的墨水并建立相应的打印方法,是今后发展的一个重要方向。而就新兴的液态金属打印墨水来说,增加其墨水种类的途径主要在于研发更多的低熔点合金材料。为此,作者所在的实验室提出了有一定纲领性的液态金属材料基因组研究计划[45],旨在为研制低熔点合金提供方向性参考,其基本技术路线在于,可将元素周期表上各金属元素加以匹配组合,并借助物理化学手段予以适当改性,同时运用相图、分子动力学及第一性原理等计算工具进行预测,最后辅以关键性实验,可筛选出合适的低熔点合金电子墨水,并研究对应的电、磁、声、光、热等物理性质。除此之外,研究液态金属墨水的润湿性,进而寻找合适的基底打印材料也是重要的研究课题。

| [1] | 崔 铮.印刷电子学[M].北京:高等教育出版社,2010. Cui Z. Printed Electronics [M]. Beijing: Higher Education Press, 2010. |

| [2] | 庄 严.印刷电子学的发展[J].电子元件与材料,2010,29(9): 1-5. Zhuang Y. Development of printed electronics [J]. Electronic Components and Materials, 2010,29(9): 1-5. |

| [3] | 辛智青,李路海,方 一,唐小君,赵 文,杜 鹏.环保型纳米尺度导电油墨研究[C].见:第二届全国精细化工清洁生产工艺与技术经济发展研讨会论文集,2009. 19-20. Xin Z Q, Li L H, Fang Y, Tang X J, Zhao W, Du P. Research of environmental friendly nano conductive ink[C]. In: The Second National Fine Chemical Clean Production Technology and Economic Development Symposium, 2009. 19-20. |

| [4] | 曹继汉. 印刷电子技术的应用与发展[C].见:2009中国高端SMT学术会议论文集,2009. 93-103. Cao J H. Application and development of printed electronics[C]. In: China High-end SMT Academic Conference Proceedings, 2009. 93-103. |

| [5] | 单 静. 无颗粒型铜导电墨水的制备及成膜研究[D]. 天津大学, 2013. Shan J. Preparation and film formation investigation of copper based particle-free conductive ink[D]. Tianjin University, 2013. |

| [6] | Hyun W J, Park O O, Chin B D. Foldable grapheme electronic circuits based on paper substrates [J]. Advanced Materials, 2013, 25(34): 4729-4734. |

| [7] | Aydemir N, Parcell J, Laslau C, Nieuwoudt M, Williams D E, Travas-Sejdic J. Direct writing of conducting polymers [J]. Macromolecular Rapid Communications, 2013, 34(16): 1296-1300. |

| [8] | Piner R D, Zhu J, Xu F, Hong S H, Mirkin C A. "Dip-pen" nanolithography [J]. Science, 1999, 283(5402): 661-663. |

| [9] | Salaita K, Wang Y H, Mirkin C A. Applications of dip-pen nanolithography [J]. Nature Nanotechnology, 2007, 2(3): 145-155. |

| [10] | Yun M H, Myung N V, Vasquez R P, Lee C S, Menke E, Penner R M. Electrochemically grown wires for individually addressable sensor arrays [J]. Nano Letters, 2004, 4(3): 419-422. |

| [11] | Yoshioka Y, Jabbour G E. Desktop inkjet printer as a tool to print conducting polymers [J]. Synthetic Metals, 2006, 156(11-13): 779-783. |

| [12] | Yun Y H, Lee B K, Choi J S, Kim S, Yoo B, Kim Y S, Park K, Cho Y W. A glucose sensor fabricated by piezoelectric inkjet printing of conducting polymers and bienzymes [J]. Analytical Sciences, 2011, 27(4): 375-379. |

| [13] | Russo A, Ahn B Y, Adams J J, Duoss E B, Bernhard J T, Lewis J A. Pen on paper flexible electronics [J]. Advanced Materials, 2011, 23(30): 3426. |

| [14] | Zhang Q, Zheng Y, Liu J. Direct writing of electronics based on alloy and metal ink (DREAM ink): a newly emerging area and its impact on energy, environment and health sciences[J]. Frontiers in Energy, 2012, 6(4): 311-340. |

| [15] | Trasande L, Landrigan P J, Schechter C. Public health and economic consequences of methyl mercury toxicity to the developing brain [J]. Environmental Health Perspectives, 2005, 113(5): 590-596. |

| [16] | Wood J M. Biological cycles for toxic elements in the environment [J]. Science, 1974, 183(4129): 1049-1052. |

| [17] | Zahir F, Rizwi S J, Haq S K, Khan R H. Low dose mercury toxicity and human health [J]. Environmental Toxicology and Pharmacology, 2005, 20(2): 351-360. |

| [18] | Sostman H E. Melting point of gallium as a temperature calibration standard [J]. Review of Scientific Instruments, 1977, 48(2): 127-130. |

| [19] | SIGMA-ALDRICH, 2011, in Adobe Reader, edited by MSDS. |

| [20] | Surmann P, Zeyat H. Voltammetric analysis using a self-renewable non-mercury electrode [J]. Analytical and Bioanalytical Chemistry, 2005, 383(6): 1009-1013. |

| [21] | Assael M J, Armyra I J, Brillo J, Stankus S V, Wu J T, Wakeham W A. Reference data for the density and viscosity of liquid cadmium, cobalt, gallium, indium, mercury, silicon, thallium, and zinc [J]. Journal of Physical and Chemical Reference Data, 2012, 41(3): 033101. |

| [22] | Dickey M D, Chiechi R C, Larsen R J, Weiss E A, Weitz D A, Whitesides G M. Eutectic gallium-indium (EGaIn): a liquid metal alloy for the formation of stable structures in microchannels at room temperature [J]. Advanced Functional Materials, 2008, 18(7): 1097-1104. |

| [23] | Alchagirov B B, Mozgovoi A G. The surface tension of molten gallium at high temperatures [J]. High Temperature, 2005, 43(5): 791-792. |

| [24] | Larsen R J, Dickey M D, Whitesides G M, Weitz D A. Viscoelastic properties of oxide-coated liquid metals [J]. Journal of Rheology, 2009, 53(6): 1305-1326. |

| [25] | Liu T Y, Sen P, Kim C J. Characterization of nontoxic liquid-metal alloy galinstan for applications in microdevices [J]. Journal of Microelectromechanical Systems, 2012, 21(2): 443-450. |

| [26] | Ma K Q, Liu J. Liquid metal cooling in thermal management of computer chip [J]. Frontiers of Energy and Power Engineering in China, 2007, 1(4): 384-402. |

| [27] | 邰艳龙. 印制电子用导电墨水的制备及应用. 复旦大学,2012. Tai Y L. Preparation and application of conductive ink for printed electronics[D]. Fudan University, 2012. |

| [28] | Glatzel S, Schnepp Z, Giordano C. From paper to structured carbon electrodes by inkjet printing [J]. Angewandte Chemie-International Edition, 2013, 52(8): 2355-2358. |

| [29] | Pidcock G C, Panhuis M I H. Extrusion printing of flexible electrically conducting carbon nanotube networks [J]. Advanced Functional Materials, 2012, 22(22): 4790-4800. |

| [30] | Xiong Z T, Liu C Q. Optimization of inkjet printed PEDOT: PSS thin films through annealing processes [J]. Organic Electronics, 2012, 13(9): 1532-1540. |

| [31] | Mo L X, Liu D Z, Li W, Li L H, Wang L C, Zhou X Q. Effects of dodecylamine and dodecanethiol on the conductive properties of nano-Ag films [J]. Applied Surface Science, 2011, 257(13): 5746-5753. |

| [32] | Lee H H, Chou K S, Huang K C. Inkjet printing of nano-sized silver colloids [J]. Nanotechnology, 2005, 16(10): 2436-2441. |

| [33] | Regan M J, Tostmann, H, Pershan P S, Magnussen O M, DiMasi E, Ocko B M, Deutsch M. X-ray study of the oxidation of lquid-gallium surfaces [J]. Physical Review B, 1997, 55(16): 10786-10790. |

| [34] | Tostmann H, DiMasi E, Pershan P S, Ocko B M, Shpyrko O G, Deutsch M. Surface structure of liquid metals and the effect of capillary waves: X-ray studies on liquid indium [J]. Physical Review B, 1999, 59(2): 783-791. |

| [35] | 李海燕,刘 静. 液态金属电子墨水与印刷基底之间的撞击作用机制研究[J]. 电子机械工程,2014,印刷中. Li H, Liu J. Investigation on the impacting mechanism of liquid metal electronic ink [J]. Electro-Mechanical Engineering, 2014, in press. |

| [36] | Liu Y, Gao M, Mei S F, Han Y T, Liu J. Ultra-compliant liquid metal electrodes with in-plane self-healing capability for dielectric elastomer actuators [J]. Applied Physics Letters, 2013, 102: 064101. |

| [37] | 李海燕,周 远,刘 静. 基于液态金属的可印刷式热电发生器及其性能评估, 中国科学E辑,2013, 44: 407-416. Li H, Zhou Y, Liu J. Liquid metal based printable thermoelectronic generator and its performance evaluation [J]. Science China Technological Sciences, 2013, 44: 407-416. |

| [38] | Gao Y X, Li H Y, Liu J. Direct writing of flexible electronics through room temperature liquid metal ink [J]. PLoS ONE, 2012, 7(9): e45485. |

| [39] | Zheng Y, He Z Z, Yang J, Liu J. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism [J]. Scientific Reports, 2014, 4: 4588. |

| [40] | Kramer R K, Boley J W, Stone H A, Weaver J C, Wood R J. Effect of microtextured surface topography on the wetting behavior of eutectic gallium-indium alloys [J]. Langmuir, 2014, 30(2): 533-539. |

| [41] | Zheng Y, He Z Z, Gao Y X, Liu, J. Direct desktop printed-circuits-on-paper flexible electronics [J]. Scientific Reports, 2013, 3: 1786. |

| [42] | Zhang Q, Gao Y X, Liu J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics [J]. Applied Phy-sics A, 2013, 113(4): 1-7. |

| [43] | Tabatabai A, Fassler A, Usiak C, Majidi C. Liquid-phase gallium-indium alloy electronics with microcontact printing [J]. Langmuir, 2013, 29(20): 6194-6200. |

| [44] | Kramer R K, Majidi C, Wood R J. Masked deposition of gallium-indium alloys for liquid-embedded elastomer conductors [J]. Advanced Functional Materials, 2013, 23(42): 5292-5296. |

| [45] | Wang L, Liu J. Liquid metal material genome: initiation of a new research track towards discovery of advanced energy materials [J]. Frontiers in Energy, 2013, 7(3): 317-332. |