近年来,印刷电子技术得到迅速发展,预计到2020年会形成超过200亿美元的市场[1]。无机材料和导电聚合物的应用,可以使印刷器件轻薄化,同时降低制造成本,目前主要应用在薄膜晶体管(TFTs)[2-4]、有机光伏[5-8]、超高频(UHF)天线[9-15]、触控面板[16-20]及太阳能电池[21-27]器件中。金属具有良好的导电性,主要用于印刷器件的连接和电极,纳米金属材料已成为印刷电子领域近年来备受关注的研究热点之一[28-32]。

具有高导电性和高透光度的透明导电膜,是制备高性能电子器件必不可少的基础材料。日常生活中接触到的含有透明导电膜的光电器件,主要有触控面板和液晶显示器,这些光电器件中通常用透明导电氧化物作为电极。电子工业最常用的透明导电氧化物是氧化铟锡(ITO)。ITO透光度高、表面电阻低,作为电极材料在太阳能电池、触摸屏和平板显示器等光电器件中应用广泛。但ITO具有脆性、制程复杂、制造成本高等缺陷。随着电子器件向轻薄、柔性发展,ITO已不能满足相应的需求,需要开发新型透明导电材料。

金属纳米材料具有优异的光电性能,在透明导电膜中有广泛的应用前景[33, 34]。目前主要有纳米结构金属薄膜、金属网格及金属纳米线搭接形成的网络结构。用金属材料制备透明导电薄膜时,为保证透明度,薄膜厚度需低于10 nm,但由于电子的表面散射作用,随着薄膜厚度的降低,金属表面电阻会急剧增加[35]。金属网格的线宽接近可见光半波长, 线距为亚微米级时,表面电阻就会接近纯银的电阻[36-38]。近年来,研究者们开发了铜、金、银纳米线形成的金属纳米线网络[39-42],以期取代ITO材料。金属纳米线网络制备的透明导电膜,尤其是银纳米线(AgNW)透明导电膜具有优异的导电性、透光性和良好的柔韧性,在柔性和大尺寸触控方面具有显著的优势,被认为是可以取代ITO的最佳材料。

制备银纳米线透明导电膜的方法包括湿法卷对卷涂布、迈耶棒涂布、抽滤、转印、旋涂、浸涂和喷涂。这些方法在制备成本上低于传统气相沉积法制备ITO,其中,卷对卷涂布法可以实现连续涂布,在制备成本方面优势明显,但需要进一步提高表面电阻、表面粗糙度、与基材的附着力及稳定性。

1 银纳米线透明导电膜的制备银纳米线透明导电膜的表面电阻,主要来源于银纳米线互相搭接形成的接触电阻。由于银纳米线表面通常附着聚乙烯吡咯烷酮(PVP)树脂绝缘层,导致银纳米线的接触电阻非常大[43, 44],有时方阻达到1 GΩ/□。研究者们开发了许多新技术以降低银纳米线间的接触电阻,提高导电膜的透明度、降低表面粗糙度,以期满足各种应用需求。

1.1 后处理通过加压和加热等后处理方法,可以使银纳米线搭接融合,降低接触电阻[45]。Tokuno等[46]在常温下对银纳米线层施加25 MPa的压力,得到电阻为8.6 Ω/□,透光度为80%的透明导电膜。Hauger等[47]在165 ℃时对银纳米线透明导电膜施加50 psi的压力,得到电阻小于20 Ω/□的透明导电膜。但是,加热温度过高或施加压力过大,银纳米线容易发生断线,电阻反而会升高。Jia等[48]报道了一种动态加热法,降低了银纳米线透明导电膜的电阻,得到电阻为35 Ω/□,透光度95%的透明导电膜,且电阻均匀性很高(不均匀系数<6.7%)。Yang等[49]用高强度激光脉冲进行后处理,得到的导电膜在100%拉伸时仍能保持电阻小于10 Ω/□。

1.2 引入其他功能组份 1.2.1 氧化石墨烯/石墨烯近年来,石墨烯(Grephene,G)作为一种性能优异的二维导电材料受到广泛重视。有研究者选择氧化石墨烯(GO)连接银纳米线[50],原因如下:(1)氧化石墨烯表面有大量含氧官能团,如羟基、环氧基、羰基、羧基等,能够与银纳米线表面的PVP形成化学键,形成强有力的结合;(2)氧化石墨烯的杨氏模量高达0.25 TPa,且具有很高的韧性;(3)氧化石墨烯价格便宜,且水溶。在溶液中带电荷的柔性氧化石墨烯片能够吸附并缠绕在银纳米线上,在银纳米线搭接处起到“焊接”作用,不经过加热或高压处理就能明显降低银纳米线之间的接触电阻。因此,氧化石墨烯/银纳米线复合网络结构,可以在聚对苯二甲酸乙二醇酯(PET)基材上形成具有良好光电性能和柔韧性的透明导电膜。

Liang等[51]在用迈耶棒涂布银纳米线后,将基板浸泡在氧化石墨烯溶液中(图 1A),得到氧化石墨烯“焊接”的银纳米线透明导电膜。该导电膜的电阻为14 Ω/□,透光度可以达到88%(550 nm)。由于氧化石墨烯的“焊接”作用,该导电膜在4 mm弯曲半径下弯折12000次后,电阻上升不到23%(图 1B)。氧化石墨烯的强力粘结和高韧性使银纳米线之间由简单搭接变为较强的“焊接”,有效防止了银纳米线之间的滑移,表现出优越的柔韧性。

|

图 1 A. GO-AgNW复合网络结构的示意图(左)及SEM图(右);B. GO-AgNW/PET透明导电膜(左)、弯曲半径4 mm的实验照片图(中)及电阻变化率图(右)[51] Fig.1 A. Left: schematic illustration of the fabrication of a GO-AgNW network on a glass substrate at room temperature; right: SEM images of GO-soldered AgNW junctions; B. Optical photograph of a GO-AgNW/PET (left) bent to 4 mm radius (middle) and relative resistance change (right) of the GO-AgNW/PETduring repeated bending-unbending test[51] |

Lu等[52]报道了GO防止银纳米线氧化的作用,并指出GO层的堆叠会降低银纳米线层的导电性,因此, 制备时在GO溶液中添加少量硼氢化钠用于还原GO,提高导电膜的导电性。Miao等[53]则将聚多巴胺改性并还原的氧化石墨烯作为导电粘结层和保护层,用于银纳米线透明导电膜中(图 2),得到电阻63 Ω/□,透光度70.5%的透明导电膜。

|

图 2 RPFGO-AgNW复合透明导电膜的制备过程示意图[53] Fig.2 Schematic illustration of the preparation process of RPFGO-AgNW hybrid TCF[53] |

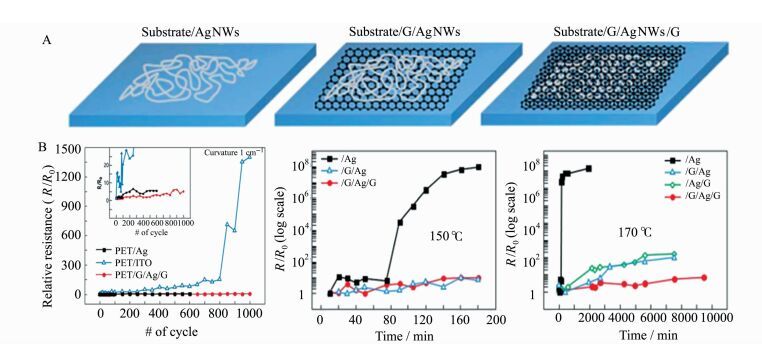

Lee等[54]将银纳米线夹在两层石墨烯(G)中间,制备了G/AgNW/G复合导电膜。同样由于石墨烯的柔韧性,该导电膜在曲率1 cm-1下弯折1000次后电阻无明显升高(图 3)。由于石墨烯导热系数高,上下两层石墨烯共同作用,不仅阻止了银原子的表面迁移,还防止了热量的聚集,该透明导电膜在170 ℃高温下稳定保存150 h,热稳定性良好。另外,石墨烯阻止了银纳米结构在350~400 nm的表面等离子体吸收,使得该透明导电膜在300~1000 nm波段的透光度均达到90%以上。

|

图 3 A. G/AgNW/G复合导电膜结构示意图;B. 弯折(左)及150 ℃(中)和170 ℃(右)高温条件下的电阻率变化图[54] Fig.3 A. Schematic illustration of the fabrication of a G/AgNW/G network; B. Left: Change in the relative resistance of electrode materials according to the number of bending cycles; Middle and right: Change in the relative resistance by heating time depending on the stacking sequence at 150 ℃ (middle) and 170 ℃(right)[54] |

在银纳米线透明导电膜中,银纳米线只覆盖了基材表面约20%的面积,银纳米线之间的空隙为绝缘的基材。对应用器件来说,银纳米线透明电极必须与器件的有效面积全部接触才能满足导电的需求[55]。一些研究者用金属氧化物颗粒作为填充涂层,以提高透明导电膜的导电性能。

Zilberberg等[56]在银纳米线上分别增加了锡氧化物(SnOx)层和铝掺杂氧化锌(AZO)层。SnOx层采用溶胶-凝胶法制备,在室温下制备有机太阳能电池的电子传输层。AZO层采用原子层沉积法制备,操作温度为100 ℃,这预示着可以开发一种在常压低温下大规模生产透明导电膜的方法。这两种方法都可以实现银纳米线搭接点的融合及银纳米线与基材的粘结,将银纳米线导电膜的电阻从90 Ω/□降到5.2 Ω/□,同时透光度在87%以上,附着力良好。

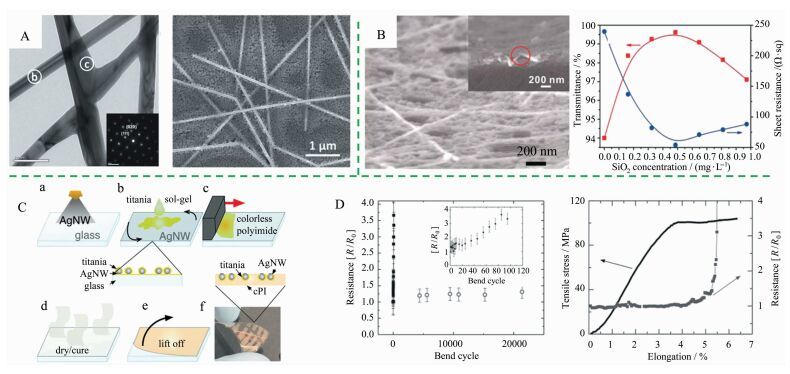

Lu等[57]将含有银离子、还原剂和稀硝酸的溶液滴在银纳米线网络中,溶液通过毛细作用渗透进入银纳米线搭接的缝隙中,还原后在搭接处形成银原子,进而将银纳米线融合(图 4A),降低搭接阻抗。他们还将二氧化硅颗粒作为涂层,填充在银纳米线未覆盖的空隙处,降低表面粗糙度。制备的银纳米线透明导电膜电阻为20.5 Ω/□。

|

图 4 A. 左:化学处理后银纳米线搭接处的TEM图,右:SiO2处理银纳米线网络后的SEM图[57];B. 左:中空微球处理银纳米线网络后的SEM图,右:导电膜的透光度-电阻图[58];C. TiO2/AgNW/PI复合导电膜制备流程示意图;D. TiO2/AgNW/cPI复合导电膜弯折(左)及拉伸后的电阻变化率图(右)[59] Fig.4 A. Left: TEM image of crossed silver nanowires after chemical treatment,right: SEM image of silver nano-network electrode after SiO2 NPs coating[57];B. Left: SEM image mixture of SiO2-HNSs and AgNWs,right: effect of SiO2-HNS concentration on transmittance and sheet resistance of AgNW-based TCFs[58];C. The fabrication process of TiO2/AgNW/PI transparent condutive film;D. Left: bending fatigue test of colorless polyimide and AgNWs on top of PET,right:tensile test of conductive cPI, the sample is taken to failure with the stress measured while the resistance is monitored[59] |

Zhang等[58]将二氧化硅中空微球(SiO2-HNSs)引入银纳米线透明导电膜中(图 4B),由于氢键及范德华力作用,提高了银纳米线在聚合物基体中的分散。由于SiO2-HNSs与银纳米线带相反电荷,电荷间引力作用缩小了银纳米线之间的距离,使透明导电膜的表面密度高、渗流电阻率低,同时也降低了银纳米线层的厚度。当厚度和折射率满足增透条件时,二氧化硅、二氧化钛等粒子具有增透作用。该法可将银纳米线透明导电膜的透光度提高14.3%,得到的透明导电膜在电阻为33 Ω/□时透光度仍高达98%(扣除基材影响)。Spechler等[59]通过溶胶-凝胶法在银纳米线透明导电膜中添加了二氧化钛涂层,由于银纳米线及二氧化钛是嵌入透明聚酰亚胺(cPI)中成膜,提高了导电膜的热稳定性(图 4C和4D),降低了表面粗糙度(均方根粗糙度<1 nm),提高了机械性能。Singh等[60]在银纳米线表面溅射一层厚度为40 nm的氧化锌,提高了银纳米线之间的搭接,降低了电阻和表面粗糙度,得到透光度92%,电阻20 Ω/□的透明导电膜。

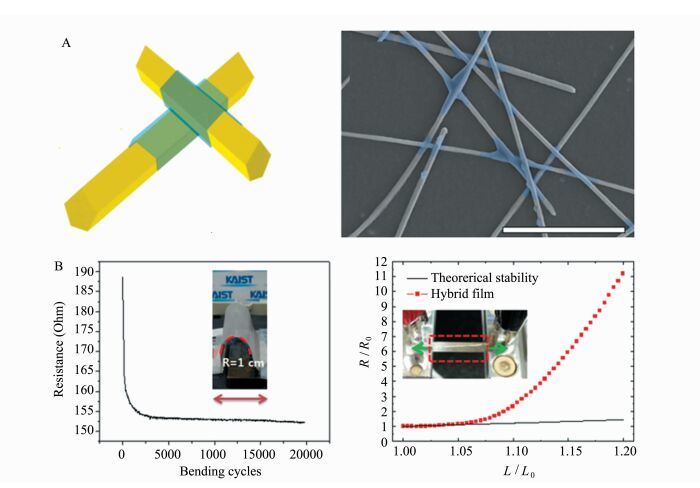

1.2.3 导电聚合物聚3, 4-乙烯二氧噻吩/聚苯乙烯磺酸盐(PEDOT∶PSS)是一种水分散导电聚合物,具有很好的导电性[61-64]。Lee等[65]将PEDOT∶PSS作为可常温“焊接”的材料用于银纳米线透明导电膜中(图 5)。在干燥过程中,PEDOT∶PSS通过毛细作用,渗透进入银纳米线搭接处,将银纳米线“焊接”在一起,降低搭接阻抗,制备的导电膜电阻为25~50 Ω/□,透光度为90%。同时,由于PEDOT∶PSS与基材的粘结作用,提高了银纳米线与基材的附着力及导电膜的机械稳定性,弯曲半径1 cm下弯折20000次或拉伸5%~10%后依然保持低电阻。Park等[66]也将PEDOT∶PSS应用于银纳米线透明导电膜中,得到了电阻为30Ω/□,透光度为86%的导电膜。

|

图 5 A. PEDOT∶PSS作用于AgNW的示意图(左)及SEM图(右);B. 弯折(左)及拉伸(右)时AgNW/PEDOT∶PSS复合导电膜的电阻变化及电阻变化率图[65] Fig.5 A. Left: schematics of the pentagonal AgNW juntion with nanosoldering by PEDOT∶PSS coating,right: SEM image of AgNWs joined by PEDOT∶PSS;B. Cyclic bending (left) and stretching test(right) of nanosoldered hybrid film on a flexible substrate and the electrical property change[65] |

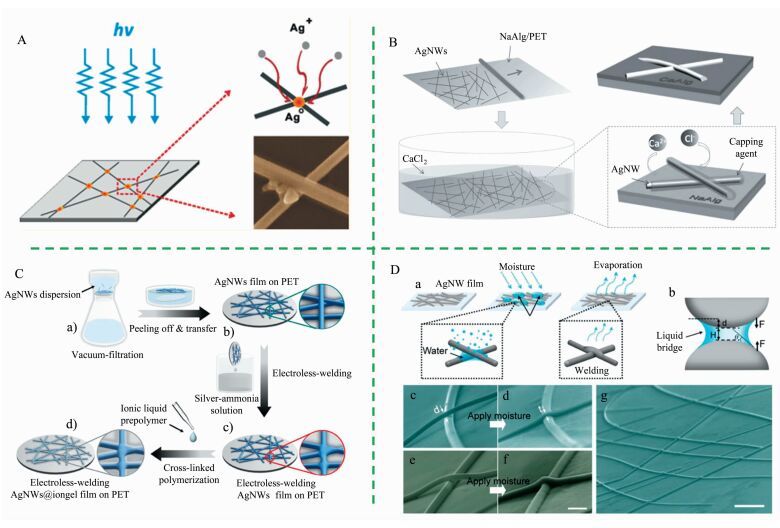

Lu等[67]通过化学还原法将银纳米粒子选择性生长在银纳米线搭接处(图 6A),降低银纳米线的接触电阻,得到的导电膜电阻21.9 Ω/□时,透光度为90.4%。

|

图 6 A. 银纳米粒子在银纳米线搭接处作用的示意图[67];B. AgNW/CaCl2复合导电膜的制备示意图[68];C. AgNWs@iongel制备流程图[70];D. 通过毛细作用促进银线搭接的示意图及SEM图[71] Fig.6 A. Schematics of the pentagonal AgNW juntion with nanosoldering by AgNPs[67];B. A schematic procedure of AgNW/CaCl2 film preparation[68];C. Fabrication of stable AgNWs@iongel composite films for flexible transparent electrodes[70];D. Schematics and SEM images of the capillary-force-induced cold welding of AgNWs[71] |

Jin等[68]将氯化钙引入银纳米线透明导电膜体系中(图 6B),使导电膜的电阻从300 Ω/□降到了53 Ω/□(透光度为94%),附着力和稳定性提高了30%以上。在该方法中,PET基材用海藻酸盐进行处理,然后引入氯化钙“焊接”银纳米线。氯化钙中的氯离子使银纳米线表面的稳定剂剥离下来,诱发“焊接”,降低接触电阻;同时,氯化钙中的二价钙离子与基材中的海藻酸反应,生成海藻酸凝胶,提高了银纳米线与基材的附着力。

Kim等[69]在银纳米线墨水中加入剥离黏土片,提高了银纳米线的分散性,改善了涂布时银纳米线的咖啡环效应,得到的透明导电膜电阻10 Ω/□时透光度为90%。

Xiong等[70]报道了一种降低银纳米线透明导电膜方阻并提高稳定性的方法。他们用真空抽滤的方法使银纳米线成膜后转移到PET上,然后将PET浸入含有葡萄糖的银氨溶液中,随即干燥,溶液中的银离子被葡萄糖还原,在银纳米线搭接处形成“焊接”,降低了搭接阻抗(图 6C),最后引入导电的离子凝胶作为导电膜的保护层,由于离子凝胶的优异物理化学稳定性及热稳定性,导电膜在空气中暴露60天后,电阻仍然没有变化(电阻8.4 Ω/□,透光度86%),显示了很高的稳定性。

在纳米尺度,毛细作用是很强的驱动力,两个相互接触的纳米颗粒之间由于毛细作用引起的压力高达10 MPa,甚至达到GPa级。Liu等[71]利用两根银纳米线之间的毛细作用,使银纳米线“焊接”,降低搭接阻抗,只需要给透明导电膜增加湿度即可实现(图 6D)。水蒸气通过毛细作用进入银纳米线搭接处,形成液桥,液桥引起的压力促使两根银线“焊接”在一起,降低了搭接阻抗。

2 银纳米线透明导电膜在光电器件中的应用银纳米线透明导电膜具有高透光度、低电阻和出色的柔韧性,被广泛研究并应用于太阳能电池、触摸屏、透明加热器、OLED、电子线路等光电器件中。

2.1 太阳能电池目前,有机太阳能电池的光电转换效率已达11.1%,银纳米线透明导电膜通常用于太阳能电池的前电极,有机太阳能电池、薄膜太阳能电池及Si/PEDOT∶PSS复合太阳能电池,都可以用银纳米线透明导电膜作为电极。

Peumans等[72]用银纳米线透明导电膜为前电极制备太阳能电池,在光强为100 mW/cm2、照度为AM1.5G时,该太阳能电池的光电转换效率可以达到2.5%(图 7A)。Yang等[73]也用银纳米线透明导电膜作为电极,采用全液相法制备了太阳能电池(图 7B)。该太阳能电池在玻璃和PET基材上的光电转换效率分别达到2.8%和2.5%。在PET基材上弯折角度达到120°时,光电转换效率仍为2.5%。Park等[66]用银纳米线透明导电膜作为电极制备的有机太阳能电池,光电转化效率达到7.15%。一般而言,光电转换效率主要受到银纳米线导电层功函数、银纳米线之间非接触电阻及表面粗糙度的影响。基于此,Xu等[74]开发了GO/AgNW透明电极,降低了银纳米线之间的接触电阻及表面粗糙度,同时增强了原位电势,光电转换效率高达13.3%(图 7C)。Singh等[60]用氧化锌镀层,降低银纳米线搭接电阻和表面粗糙度制备的低电阻透明导电膜作为电极,制备的CuInGaSe2太阳能电池的光电转化效率达13.5%(图 7D)。

|

图 7 A. 左:用银纳米线为电极的聚合物太阳能电池的结构图,右:在120°弯曲情况下柔性器件的J-V特征图[72];B. 左:基于银纳米线的太阳能电池器件结构层压结构图,右:器件的J-V特征图[73];C. 左:PEDOT∶PSS/AgNW/GO复合电极结构图,右:复合电极器件的J-V特征图[74];D. 左:AgNW(ZnO)复合导电膜结构图,右:以此导电膜为电极制备太阳能电池器件的J-V图[60] Fig.7 A. Left: The device structure of the solution-processed BHJ polymer solar cell with the AgNW anode,right:characteristic J-V curves off flexible devices under large deformation up to 120°[72];B. Left: Device structure and lamination process; right: current density-voltage (J-V) characteristics for the partially optimized organic PV cells[73];C. Left: schematic diagram of the Si/PEDOT∶PSS hybrid solar cells based on the PEDOT∶PSS/AgNW/GO composite TCEs,right: current density versus voltage characteristics of the hybrid solar cells based on AgNW/GO composite TCEs[74];D. Left:schematic presentation of TCE employing AgNW(ZnO) for CIGS solar cell,right: J-V curves of CIGS solar cells fabricated using AgNW(ZnO)[60] |

需要注意的是,ITO透明导电膜的功函数为4.4 eV,银纳米线透明导电膜的功函数为4.0 eV,在制备太阳能电池时需要考虑两者功函数的差异,使能级匹配,以便器件正常工作。另外,可以通过调整银纳米线透明导电膜的表面粗糙度等参数,满足高效率太阳能电池的需求,而对于ITO膜来说,这一点很难做到。与ITO透明导电膜相比,银纳米线透明导电膜具有优异的柔韧性,因此在柔性器件中有很大的优势。

2.2 触控显示通过触控界面操作的设备已广泛用于电子器件,例如平板显示器和智能手机显示屏等。对于触控显示来说,要求透明导电膜具有低雾度。导电膜的电阻决定了触摸屏的激活电压、显示精度及响应时间。另外,导电膜的均匀性也是影响触摸屏性能的重要指标。

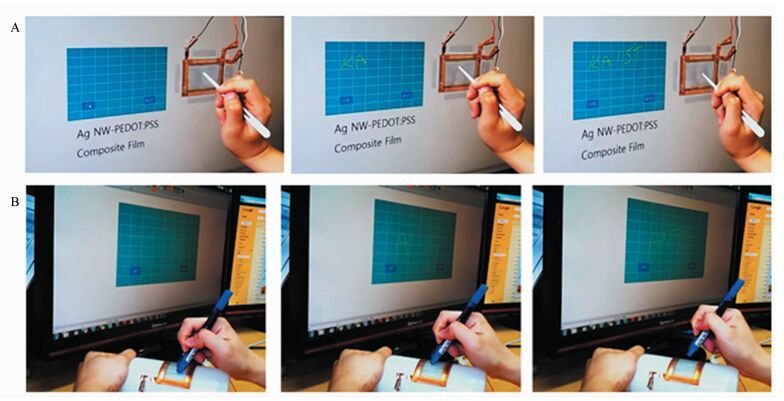

Lee等[19]用AgNW/PEDOT∶PSS体系制备出用于触控显示面板的透明导电膜。PEDOT∶PSS在干燥过程中渗透进入银纳米线搭接的缝隙中,降低了银纳米线的接触电阻。当该体系用在柔性基材上时,可以制备柔性触控显示面板, 如图 8A所示;触控显示面板在手臂上缠绕时依然可以写入信息, 如图 8B所示。

|

图 8 触控显示面板操作图(A)和 可弯曲触控显示面板在人手臂上的操作图(B)[19] Fig.8 A. Video clips of the touch screen operation;B. Demonstration of a bendable touch screen on a non-flat surface[19] |

Bari等[75]制备了长度200~500 μm、直径45~65 nm的银纳米线,并用于透明导电膜,该导电膜电阻10 Ω/□时透光度为90%,且均匀性良好,应用于触摸屏实现了柔性显示。Moon等[76]也制备了长度200 μm,直径45 nm的银纳米线用于透明导电膜,该导电膜透光度为96%,电阻为100 Ω/□,雾度为2%,且用于柔性显示触摸屏。Jang等[77]将金属网格引入银纳米线透明导电膜体系中(图 9A),增加了导电膜的均匀性。Jia等[48]用动态加热法制备的银纳米线透明导电膜也具有高均匀性(图 9B)。这两种方法制备的导电膜应用于触摸屏都有良好的性能,可实现柔性显示。

|

图 9 A. 上:AG/NW复合导电膜结构及器件结构图,下:触控显示写入信息图[77];B. 左:电阻不均匀度柱状图,右:制备触控显示器件后写入信息图[48] Fig.9 A. Top: touch-screen panel (TSP) device using the AG/NW-GFRHybrimer films,down: photographs for the operating TSP device by human hand. The written characters read “KAIST”[77];B. Left: Histogram of the measured sheet resistance,right: demonstration for exact writing input using the uniform AgNW TCFs[48] |

性能优异、低成本的透明导电膜是制备大面积OLEDs的关键。电阻高会导致OLEDs的驱动电压高、产生热量高、发光不均匀,且器件容易老化,降低使用寿命;透光度低会降低器件的外量子效率。透明导电膜基材的柔韧性使OLEDs可以采用低成本的卷对卷涂布,便于制备大面积OLEDs器件。由于ITO成本高,且在柔性PET基材上的电阻比在玻璃基材上高5倍以上,所以研究者们开发了新型透明导电膜用于OLEDs,以期取代ITO。

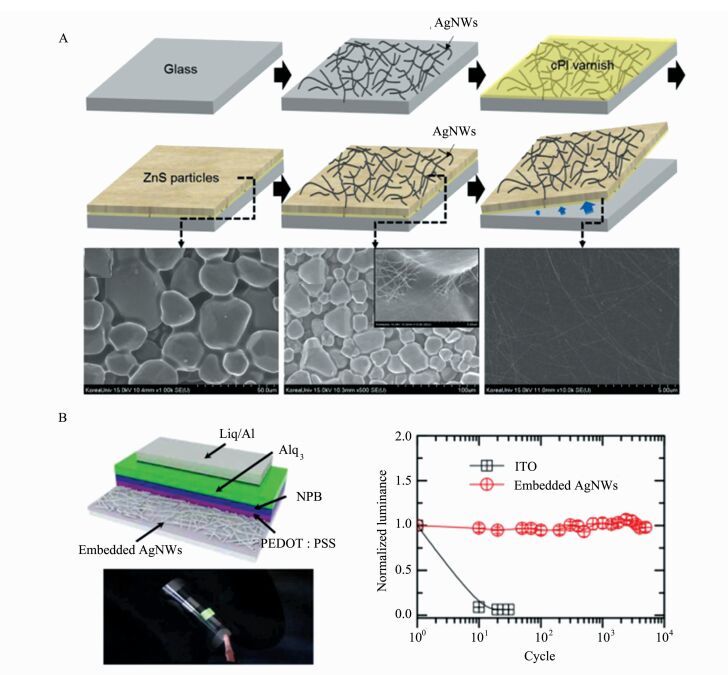

Liu等[78]用有序排列的银纳米线为电极,表面粗糙度小于15 nm,制备的OLEDs在亮度为60 cd/m2时最大电流效率为54.4 cd/A,亮度为1000 cd/m2时最大电流效率为49.0 cd/A。与ITO为电极的OLEDs相比,发光效率提高了40%。Jun等[79]制备银纳米线/透明聚酰亚胺(cPI)复合透明导电膜,表面粗糙度可以降低到4.5 nm。用该材料作为电极和介质层制备了双面发光的OLEDs器件,器件柔韧性良好,弯曲半径0.3 mm下弯折5000次,发光强度降低小于11%(图 10A)。

|

图 10 A. 上:制备银纳米线复合导电膜的流程示意图,下:ZnS颗粒,沉积银纳米线后的ZnS颗粒及嵌入银纳米线后cPI表面的SEM图[79];B. 左:银纳米线透明导电膜为电极制备OLED的结构示意图及弯曲状态下的发光图,右:弯折测试后发光效率图[80] Fig.10 A. Top: schematic of fabrication procedure for flexible ACEL devices,down: SEM micrograph of ZnS particles, AgNWs deposited on top of the ZnS phosphorescent particles, and fully embedded AgNWs at the cPI surface[79];B. Left: schematic diagram showing the device structure of the OLED based on the embedded AgNW anode electrode and the lower panel shows a light emission image of the device under bending,right: mechanical stability of the OLEDs prepared using ITO or embedded AgNW anode electrodes[80] |

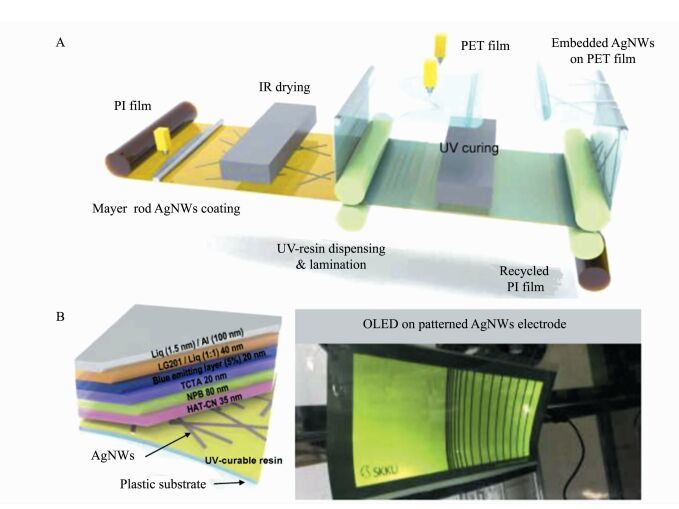

Kang等[80]将银纳米线嵌入树脂中,通过光固化方法实现图案化,制备了表面粗糙度为4.7 nm的银纳米线透明电极。用于OLEDs器件,在弯折5000次及拉伸2.75%时发光效率不受影响(图 10B)。Jung等[81]用卷对卷方式制备了电阻均匀度高达97.5%的银纳米线透明导电膜,用在OLEDs上,发光效率比ITO电极提高了30%~40%(图 11)。Ye等[82]在银纳米线导电膜上打印金属网格后作为电极制备柔性OLEDs,在弯曲半径为2 mm时可以保持最大亮度10000 cd/m2,最大电流效率12 cd/A。

|

图 11 A. 卷对卷工艺在PET基材上制备银纳米线电极的示意图;B. 左:OLED器件结构的截面图,右:OLED器件发光图[81] Fig.11 A. Schematic illustration of the roll-to-roll fabrication process for the embedded AgNWs transparent electrode on PET film;B. Left: cross-sectional OLED structure,right: OLED on the embedded AgNWs/PET[81] |

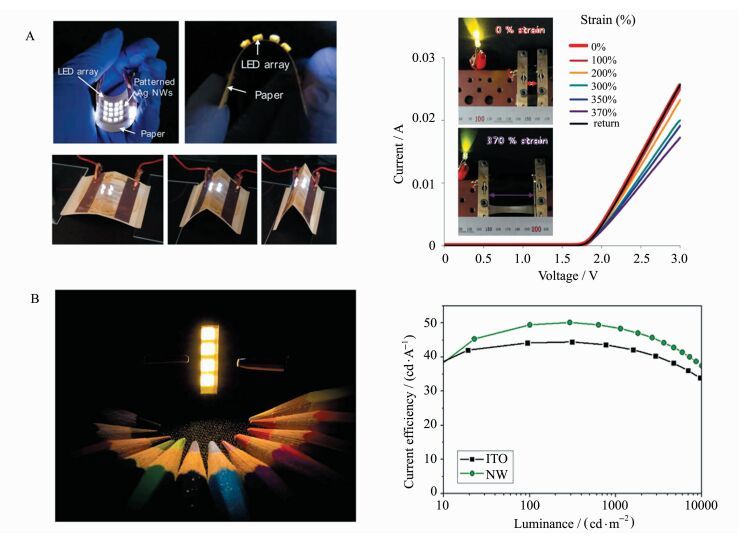

Lee等[83]用长银纳米线制备了透明电极,电极拉伸率370%时,仍能使OLEDs灯发光,柔韧性良好(图 12A)。Gaynor等[84]用液相法制备了复合透明电极用于高效率白光OLEDs,该电极用全液相法将银纳米线渗透进入聚甲基丙烯酸甲酯(PMMA)薄膜中形成(图 12B),白光OLEDs发光效率超过30 lm/W。由于这种纳米线透明电极具有低电阻和低光散射特性,增加了电流效率,发光效率接近完美的Lambertian模型,与ITO为电极制备的器件相比,发光稳定性出色。

|

图 12 A. 左:用银纳米线为电极的柔性纸显示器在不同弯曲半径时发光的示意图,右:拉伸率超过370%时器件的发光效果图及C-V图[83];B. 左:银纳米线为电极制备白光OLEDs的发光图,右:白光OLEDs发光电流效率图[84] Fig.12 A. Left: images of a flexible paper display with 4 ×4 array of LEDs with Ag nanowire electrodes and images of a flexible paper display under various bending radii,right:current-voltage measurement of the LED integrated stretchable electrode using a Ag nanowire conductor on a highly elastic substrate at various tensile strains (over 370%). Insets show the digital images of the LED integrated circuits operating at 0 and 370% strain[83];B. Left: photographic image of four operating NW-OLEDs,right:current efficiency of the white tandem OLEDs with nanowire and ITO anode[84] |

ITO玻璃已经主导透明导电膜市场几十年,目前仍然是应用最多和最广泛的透明导电材料。然而,随着便携式电子器件的发展,出现了许多新型透明导电膜,其中一些导电膜的性能,尤其是在柔性方面远远超过了ITO玻璃。银纳米线透明导电膜整体性能优异,生产成本低,与现有生产线匹配性高,最有可能取代ITO实现规模应用。

但是,银纳米线透明导电膜应用在商业化电子器件中之前,仍然有一些技术壁垒需要攻克,如:电阻均匀性、雾度、长期环境稳定性等。未来,银纳米线透明导电膜的研究重点应涵盖以下几个方面:

(1)优化银纳米线的尺寸及批量制备的稳定性,包括长度、直径、长径比。

(2)开发雾度低于1%的银纳米线透明导电膜,满足应用需求。

(3)提高银纳米线透明导电膜在热、化学刻蚀和机械应力下的长期稳定性。

(4)开发银纳米线透明导电膜在柔性电子器件中的应用。

随着越来越多研究者和企业的加入,相信在不久的将来,银纳米线透明导电膜将会成为下一代透明导电膜中的佼佼者。

致谢 感谢国家自然科学基金(21303218, 21671193, 21301180)、北京市重点科技项目(D151100003315001)和北京市绿色印刷与出版协同创新中心项目(04190116008/002)的支持。| [1] | Perelaer J, Smith P J, Mager D, Soltman D, Volkman S K, Subramanian V, Korvink J G, Schubert U S. Printed electronics:the challenges involved in printing devices, interconnects, and contacts based on inorganic materials[J]. Journal of Materials Chemistry, 2010, 20(39): 8446–8453. DOI:10.1039/c0jm00264j |

| [2] | Zhai Y J, Mathew L, Rao R, Xu D W, Banerjee S K. High-performance flexible thin-film transistors exfoliated from bulk wafer[J]. Nano Letters, 2012, 12(11): 5609–5615. DOI:10.1021/nl302735f |

| [3] | Sun J, Zhang B, Katz H E. Materials for printable, transparent, and low-voltage transistors[J]. Advanced Functional Materials, 2011, 21(1): 29–45. DOI:10.1002/adfm.201001530 |

| [4] | Wu Y L, Li Y N, Ong B S. Printed silver ohmic contacts for high-mobility organic thin-film transistors[J]. Journal of the American Chemical Society, 2006, 128(13): 4202–4203. DOI:10.1021/ja058725w |

| [5] | ImH G, Jung S H, Jin J, Lee D, Lee J Y, Kim I D, Bae B S. Flexible transparent conducting hybrid film using a surface-embedded copper nanowire network:a highly oxidation-resistant copper nanowire electrode for flexible optoelectronics[J]. ACS Nano, 2014, 8(10): 10973–10979. DOI:10.1021/nn504883m |

| [6] | Gioti M, Kokkinos D, Chaidou C I, Laskarakis A, Andreopoulou A K, Kallitsis J K, Logothetidis S. A comprehensive study of the optical properties of emitting polymers for efficient flexible OLED devices[J]. Physica Status Solidi, 2016, 213(11): 2947–2953. DOI:10.1002/pssa.201600651 |

| [7] | Matsuzaki J, Yamae K. Development of highly efficient light extraction technology with nano-structure for OLED devices[J]. Journal of Photopolymer Science & Technology, 2015, 28(3): 329–334. |

| [8] | Bishop P T, Ashfield L J, Berzins A, Boardman A, Buche V, Cookson J, Gordon R J, Salcianu C, Sutton P. Printed gold for electronic applications[J]. Gold Bulletin, 2010, 43(3): 181–188. DOI:10.1007/BF03214985 |

| [9] | Allen M L, Jaakkola K, Nummila K, Seppa H. Applicability of metallic nanoparticle inks in RFID applications[J]. IEEE Transactions on Components and Packaging Technologies, 2009, 32(2): 325–332. DOI:10.1109/TCAPT.2008.2010505 |

| [10] | Gao Z Q, Zhao X P. Nanosilver conductive ink inkjet printing RFID tag antenna[J]. Applied Mechanics and Materials, 2014, 469: 322–325. |

| [11] | Komoda N, Nogi M, Suganuma K, Kohno K, Akiyama Y, Otsuka K. Printed silver nanowire antennas with low signal loss at high-frequency radio[J]. Nanoscale, 2012, 4(10): 3148–3153. DOI:10.1039/c2nr30485f |

| [12] | Li Z, Le T R, Wu Z K, Yao Y G, Li L Y, Tentzeris M, Moon K S, Wong C P. Rational design of a printable, highly conductive silicone-based electrically conductive adhesive for stretchable radio-frequency antennas[J]. Advanced Functional Materials, 2015, 25(3): 464–470. DOI:10.1002/adfm.201403275 |

| [13] | Song L N, Myers A C, Adams J J, Zhu Y. Stretchable and reversibly deformable radio frequency antennas based on silver nanowires[J]. ACS Applied Materials Interfaces, 2014, 6(6): 4248–4253. DOI:10.1021/am405972e |

| [14] | Vural M, Crowgey B, Kempel L C, Kofinas P. Nanostructured flexible magneto-dielectrics for radio frequency applications[J]. Journal of Materials Chemistry C, 2014, 2(4): 756–763. DOI:10.1039/C3TC32113D |

| [15] | Wolf F M, Perelaer J, Stump S, Bollen D, Kriebel F, Schubert U S. Rapid low-pressure plasma sintering of inkjet-printed silver nanoparticles for RFID antennas[J]. Journal of Materials Research, 2013, 28(9): 1254–1261. DOI:10.1557/jmr.2013.73 |

| [16] | Hong S, Yeo J, Kim G, Kim D, Lee H, Kwon J, Lee H, Lee P, Ko S H. Nonvacuum, maskless fabrication of a flexible metal grid transparent conductor by low-temperature selective laser sintering of nanoparticle ink[J]. ACS Nano, 2013, 7(6): 5024–5031. DOI:10.1021/nn400432z |

| [17] | Li R Z, Hu A, Zhang T, Oakes K D. Direct writing on paper of foldable capacitive touch pads with silver nanowire inks[J]. ACS Applied Materials Interfaces, 2014, 6(23): 21721–21729. DOI:10.1021/am506987w |

| [18] | Lee J, Lee P, Lee H, Lee D, Lee S S, Ko S H. Very long Ag nanowire synthesis and its application in a highly transparent, conductive and flexible metal electrode touch panel[J]. Nanoscale, 2012, 4(20): 6408–6414. DOI:10.1039/c2nr31254a |

| [19] | Lee J, Lee P, Lee H B, Hong S, Lee I, Yeo J, Lee S S, Kim T, Lee D, Ko S H. Room-temperature nanosoldering of a very long metal nanowire network by conducting-polymer-assisted joining for a flexible touch-panel application[J]. Advanced Functional Materials, 2013, 23(34): 4171–4176. DOI:10.1002/adfm.v23.34 |

| [20] | Hsu P C, Wang S, Wu H, NarasimhanV K, Kong D, Lee H R, Cui Y. Performance enhancement of metal nanowire transparent conducting electrodes by mesoscale metal wires[J]. Nature Communications, 2013, 4: 2522–2529. |

| [21] | Maisch P, Tam K C, Lucera L, Egelhaaf H J, Scheiber H, Maier E, Brabec C J. Inkjet printed silver nanowire percolation networks as electrodes for highly efficient semitransparent organic solar cells[J]. Organic Electronics, 2016, 38: 139–143. DOI:10.1016/j.orgel.2016.08.006 |

| [22] | Kim A, Lee H, Kwon H C, Jung H S, Park N G, Jeong S, Moon J. Fully solution-processed transparent electrodes based on silver nanowire composites for perovskite solar cells[J]. Nanoscale, 2016, 8(12): 6308–6316. DOI:10.1039/C5NR04585A |

| [23] | Liang J, Bi H, Wan D Y, Huang F Q. Novel Cu nanowires/graphene as the back contact for CdTe solar cells[J]. Advanced Functional Materials, 2012, 22(6): 1267–1271. DOI:10.1002/adfm.v22.6 |

| [24] | Lu H F, Zhang D, Ren X G, Liu J, Choy W C H. Selective growth and integration of silver nanoparticles on silver nanowires at room conditions for transparent nano-network electrode[J]. ACS Nano, 2014, 8(10): 10980–10987. DOI:10.1021/nn504969z |

| [25] | Sachse C, Wei N, Gaponik N, Müller-Meskamp L, Eychmüller A, Leo K. ITO-free, small-molecule organic solar cells on spray-coated copper-nanowire-based transparent electrodes[J]. Advanced Energy Materials, 2014, 4(2): 1300737–1300743. DOI:10.1002/aenm.201300737 |

| [26] | Stewart I E, Rathmell A R, Yan L, Ye S R, Flowers P F, You W, Wiley B J. Solution-processed copper-nickel nanowire anodes for organic solar cells[J]. Nanoscale, 2014, 6(11): 5980–5988. DOI:10.1039/c4nr01024h |

| [27] | Stewart I E, Rathmell A R, Yan L, Ye S R, Flowers P F, You W, Wiley B J. Solution-processed copper-nickel nanowire anodes for organic solar cells[J]. Nanoscale, 2014, 6(11): 5980–5988. DOI:10.1039/c4nr01024h |

| [28] | Li R Z, Hu A, Bridges D, Zhang T, Oakes K D, Peng R, Tumuluri U, Wu Z L, Feng Z L. Robust Ag nanoplate ink for flexible electronics packaging[J]. Nanoscale, 2015, 7(16): 7368–7377. DOI:10.1039/C5NR00312A |

| [29] | Yeo J, Kim G, Hong S, Kim M S, Kim D, Lee J, Lee H B, Kwon J, Suh Y D, Kang H W, Sung H J, Choi J H, Hong W H, Ko J M, Lee S H, Choa S H, Ko S H. Flexible supercapacitor fabrication by room temperature rapid laser processing of roll-to-roll printed metal nanoparticle ink for wearable electronics application[J]. Journal of Power Sources, 2014, 246: 562–568. DOI:10.1016/j.jpowsour.2013.08.012 |

| [30] | Boland J J. Flexible electronics:within touch of artificial skin[J]. Nature Materials, 2010, 9(10): 790–792. DOI:10.1038/nmat2861 |

| [31] | Takei K, Takahashi T, Ho J C, Ko H, Gillies A G, Leu P W, Fearing R S, Javey A. Nanowire active-matrix circuitry for low-voltage macroscale artificial skin[J]. Nature Materials, 2010, 9(10): 821–826. DOI:10.1038/nmat2835 |

| [32] | Amjadi M, Pichitpajongkit A, Lee S, Ryu S, Park I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite[J]. ACS Nano, 2014, 8(5): 5154–5163. DOI:10.1021/nn501204t |

| [33] | Lassiter J B, McGuire F, Mock J J, Ciracì C, Hill R T, Wiley B J, Chilkoti A, Smith D R. Plasmonic waveguide modes of film-coupled metallic nanocubes[J]. Nano Letters, 2013, 13(12): 5866–5872. DOI:10.1021/nl402660s |

| [34] | Yim J H, Joe S Y, Pang C, Lee K M, Jeong H, Park J Y, Ahn Y H, Mello J C, Lee S. Fully solution-processed semitransparent organic solar cells with a silver nanowire cathode and a conducting polymer anode[J]. ACS Nano, 2014, 8(3): 2857–2863. DOI:10.1021/nn406672n |

| [35] | Meital S B, Hossam H. Flexible sensors based on nanoparticles[J]. ACS Nano, 2013, 7(10): 8366–8378. DOI:10.1021/nn402728g |

| [36] | Kuang M X, Wang L B, Song Y L. Controllable printing droplets for high-resolution patterns[J]. Advanced Materials, 2014, 26(40): 6950–6958. DOI:10.1002/adma.v26.40 |

| [37] | Su B, Wang S T, Wu Y C, Chen X, Song Y L, Jiang L. Small molecular nanowire arrays assisted by super hydrophobic pillar-structured surfaces with high adhesion[J]. Advanced Materials, 2012, 24(20): 2780–2785. DOI:10.1002/adma.v24.20 |

| [38] | Su B, Wang S T, Ma J, Wu Y C, Chen X, Song Y L, Jiang L. Elaborate positioning of nanowire arrays contributed by highly adhesive super hydrophobic pillar-structured substrates[J]. Advanced Materials, 2012, 24(4): 559–564. DOI:10.1002/adma.201104019 |

| [39] | Ye S R, Rathmell A R, Chen Z F, Stewart I E, Wiley B J. Metal nanowire networks:the next generation of transparent conductors[J]. Advanced Materials, 2014, 26(39): 6670–6687. DOI:10.1002/adma.v26.39 |

| [40] | Chen J Y, Wiley B J, Xia Y N. One-dimensional nanostructures of metals:large-scale synthesis and some potential applications[J]. Langmuir, 2007, 23(8): 4120–4129. DOI:10.1021/la063193y |

| [41] | Zhang D Q, Wang R R, Wen M C, Weng D, Cui X, Sun J, Li H X, Lu Y F. Synthesis of ultralong copper nanowires for high-performance transparent electrodes[J]. Journal of the American Chemical Society, 2012, 134(35): 14283–14286. DOI:10.1021/ja3050184 |

| [42] | Guo H Z, Lin N, Chen Y Z, Wang Z W, Xie Q S, Zheng T C, Gao N, Li S P, Kang J Y, Cai D J, Peng D L. Copper nanowires as fully transparent conductive electrodes[J]. Scientific Reports, 2013, 3: 2323–2330. DOI:10.1038/srep02323 |

| [43] | Hu L B, Kim H S, Lee J Y, Peumans P, Cui Y. Scalable coating and properties of transparent, flexible, silver nanowire electrodes[J]. ACS Nano, 2010, 4(5): 2955–2963. DOI:10.1021/nn1005232 |

| [44] | Madaria A R, Kumar A, Ishikawa F N, Zhou C W. Uniform, highly conductive, and patterned transparent films of a percolating silver nanowire network on rigid and flexible substrates using a dry transfer technique[J]. Nano Research, 2010, 3(8): 564–573. DOI:10.1007/s12274-010-0017-5 |

| [45] | Liu C H, Yu X. Silver nanowire-based transparent, flexible, and conductive thin film[J]. Nanoscale Research Letters, 2011, 6(1): 75–83. DOI:10.1186/1556-276X-6-75 |

| [46] | Tokuno T, Nogi M, Karakawa M, Jiu J T, Nge T T, Aso Y, Suganuma K. Fabrication of silver nanowire transparent electrodes at room temperature[J]. Nano Research, 2011, 4(12): 1215–1222. DOI:10.1007/s12274-011-0172-3 |

| [47] | Hauger T C, Al-Rafia S M I, Buriak J M. Rolling silver nanowire electrodes:simultaneously addressing adhesion, roughness, and conductivity[J]. ACS Applied Materials & Interfaces, 2013, 5(23): 12663–12671. |

| [48] | Jia Y G, Chen C, Jia D, Li S X, Ji S L, Ye C H. Silver nanowire transparent conductive films with high uniformity fabricated via a dynamic heating method[J]. ACS Applied Materials & Interfaces, 2016, 8(15): 9865–9871. |

| [49] | Yang Y, Ding S, Araki T, Jiu J T, Sugahara T, Wang J, Vanfleteren J, Sekitani T, Suganuma K. Facile Fabrication of stretchable Ag nanowires/polyurethane electrode based on high intensity pulsed light technique[J]. Nano Research, 2016, 9(2): 401–414. DOI:10.1007/s12274-015-0921-9 |

| [50] | Cui Y, Wang T, Zhou D, Cheng Q Y, Zhang C S, Sun S Q, Liu W, Han B H. Growth of silver film on graphene oxide pattern[J]. The Journal of Physical Chemistry C, 2012, 116(33): 17698–17704. DOI:10.1021/jp3055944 |

| [51] | Liang J J, Li L, Tong K, Ren Z, Hu W, Niu X F, Chen Y S, Pei Q B. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light emitting diodes[J]. ACS Nano, 2014, 8(2): 1590–1600. DOI:10.1021/nn405887k |

| [52] | Lu H F, Sun J S, Zhang H, Lu S M, Wallace C H C. Room-temperature solution-processed and metal oxide-free nano-composite for the flexible transparent bottom electrode of perovskite solar cells[J]. Nanoscale, 2016, 8(11): 5946–5953. DOI:10.1039/C6NR00011H |

| [53] | Miao J L, Liu H H, Li W, Zhang X X. Conductive adhesion promoter and protective layer for silver nanowire transparent electrodes[J]. Langmuir, 2016, 32(2): 5365–5372. |

| [54] | Lee J, Lee A, Yu H K. Graphene protected Ag nanowires:blocking of surface migration for thermally stable and wide range-wavelength transparent flexible electrodes[J]. RSC Advances, 2016, 6(88): 84985–84989. DOI:10.1039/C6RA17173G |

| [55] | Layani M, Kamyshny A, Magdassi S. Transparent conductors composed of nanomaterials[J]. Nanoscale, 2014, 6(11): 5581–5591. DOI:10.1039/C4NR00102H |

| [56] | Zilberberg K, Gasse F, Pagui R, Polywka A, Behrendt A, Trost S, Heiderhoff R, G rrn P, Riedl T. Highly robust indium-free transparent conductive electrodes based on composites of silver nanowires and conductive metal oxides[J]. Advanced Functional Materials, 2014, 24(12): 1671–1678. DOI:10.1002/adfm.v24.12 |

| [57] | Lu H F, Zhang D, Cheng J Q, Liu J, Mao J, Choy W C H. Locally welded silver nano-network transparent electrodes with high operational stability by a simple alcohol-based chemical approach[J]. Advanced Functional Materials, 2015, 25(27): 4211–4218. DOI:10.1002/adfm.v25.27 |

| [58] | Zhang L W, Zhang L J, Qiu Y J, Ji Y, Liu Y, Liu H, Li G J, Guo Q Q. Improved performance by SiO2 hollow nanospheres for silver nanowire-based flexible transparent conductive films[J]. ACS Applied Materials & Interfaces, 2016, 8(40): 27055–27063. |

| [59] | Spechler J A, Koh T W, Herb J T, Rand B P, Arnold C B. A transparent, smooth, thermally robust, conductive polyimide for flexible electronics[J]. Advanced Functional Materials, 2015, 25(48): 7428–7434. DOI:10.1002/adfm.v25.48 |

| [60] | Singh M, Rana T R, Kim S Y, Kim K, Yun J H, Kim J H. Silver nanowires binding with sputtered ZnO to fabricate highly conductive and thermally stable transparent electrode for solar cell applications[J]. ACS Applied Materials & Interfaces, 2016, 8(20): 12764–12771. |

| [61] | Ke L, Lai S C, Liu H, Peh C K, Wang B, Teng J H. Ultrasmooth silver thin film on PEDOT:PSS nucleation layer for extended surface plasmon propagation[J]. ACS Applied Materials Interfaces, 2012, 4(3): 1247–1253. DOI:10.1021/am201391f |

| [62] | Yang L Q, Zhang T, Zhou H X, Price S C, Wiley B J, You W. Solution-processed flexible polymer solar cells with silver nanowire electrodes[J]. ACS Applied Materials Interfaces, 2011, 3(10): 4075–4084. DOI:10.1021/am2009585 |

| [63] | Xu Q J, Song T, Cui W, Liu Y Q, Xu W D, Lee S T, Sun B Q. Solution-processed highly conductive PEDOT:PSS/AgNW/GO transparent film for efficient organic-Si hybrid solar cells[J]. ACS Applied Materials Interfaces, 2015, 7(5): 3272–3279. DOI:10.1021/am508006q |

| [64] | Lee J, Lee P, Lee H B, Hong S, Lee I, Yeo J, Lee S S, Kim T S, Lee D, Ko S H. Room-temperature nanosoldering of a very long metal nanowire network by conducting-polymer-assisted joining for a flexible touch-panel application[J]. Advanced Functional Materials, 2013, 23(34): 4171–4176. DOI:10.1002/adfm.v23.34 |

| [65] | Park Y, Bormann L, Müller-Meskamp L, Vandewal K, Leo K. Efficient flexible organic photovoltaics using silver nanowires and polymer based transparent electrodes[J]. Organic Electronics, 2016, 36(9): 68–72. |

| [66] | Gaynor W, Lee J Y, Peumans P. Fully solution-processed inverted polymer solar cells with laminated nanowire electrodes[J]. ACS Nano, 2010, 4(1): 30–34. DOI:10.1021/nn900758e |

| [67] | Lu H F, Zhang D, Ren X G, Liu J, Choy W C H. Selective growth and integration of silver nanoparticles on silver nanowires at room conditions for transparent nano-network electrode[J]. ACS Nano, 2014, 8(10): 10980–10987. DOI:10.1021/nn504969z |

| [68] | Jin Y X, Li L, Cheng Y R, Kong L Q, Pei Q B, Xiao F. Cohesively enhanced conductivity and adhesion of flexible silver nanowire networks by biocompatible polymer sol-gel transition[J]. Advanced Functional Materials, 2015, 25(10): 1581–1587. DOI:10.1002/adfm.201403293 |

| [69] | Kim T Y, Kim Y W, Lee H S, Kim H K, Yang W S, Suh K S. Uniformly interconnected silver-nanowire networks for transparent film heaters[J]. Advanced Functional Materials, 2013, 23(10): 1250–1255. DOI:10.1002/adfm.v23.10 |

| [70] | Xiong W W, Liu H L, Chen Y Z, Zheng M L, Zhao Y Y, Kong X B, Wang Y, Zhang X Q, Kong X Y, Wang P F, Jiang L. Highly conductive, air-stable silver nanowire@iongel composite films toward flexible transparent electrodes[J]. Advanced Materials, 2016, 28(33): 7167–7172. DOI:10.1002/adma.201600358 |

| [71] | Liu Y, Zhang J M, Gao H, Wang Y, Liu Q X, Huang S Y, Guo C F, Ren Z F. Capillary-force-induced cold welding in silver-nanowire-based flexible transparent electrodes[J]. Nano Letters, 2017, 17(2): 1090–1096. DOI:10.1021/acs.nanolett.6b04613 |

| [72] | Gaynor W, Lee J Y, Peumans P. Fully solution-processed inverted polymer solar cells with laminated nanowire electrodes[J]. ACS Nano, 2010, 4(1): 30–34. DOI:10.1021/nn900758e |

| [73] | Yang L Q, Zhang T, Zhou H X, Price S C, Wiley B J, You W. Solution-processed flexible polymer solar cells with silver nanowire electrodes[J]. ACS Applied Materials Interfaces, 2011, 3(10): 4075–4084. DOI:10.1021/am2009585 |

| [74] | Xu Q J, Song T, Cui W, Liu Y Q, Xu W D, Lee S T, Sun B Q. Solution-processed highly conductive PEDOT:PSS/AgNW/GO transparent film for efficient organic-Si hybrid solar cells[J]. ACS Applied Materials Interfaces, 2015, 7(5): 3272–3279. DOI:10.1021/am508006q |

| [75] | Bari B, Lee J, Jang T, Won P, Ko S H, Alamgir K, Arshadd M, Guo L J. Simple hydrothermal synthesis of very-long and thin silver nanowires and their application in high quality transparent electrodes[J]. Journal of Materials Chemistry A, 2016, 4(29): 11365–11371. DOI:10.1039/C6TA03308C |

| [76] | Moon H, Won P, Lee J, Ko S H. Low-haze, annealing-free, very long Ag nanowire synthesis and its application in a flexible transparent touch panel[J]. Nanotechnology, 2016, 27(29): 295201–295211. DOI:10.1088/0957-4484/27/29/295201 |

| [77] | Jang J, Im H G, Jin J, Lee J, Lee J Y, Bae B S. A flexible and robust transparent conducting electrode platform using an electroplated silver grid/surface-embedded silver nanowire hybrid structure[J]. ACS Applied Materials & Interfaces, 2016, 8(40): 27035–27043. |

| [78] | Liu S Y, Ho S, So F. Novel Patterning method for silver nanowire electrodes for thermal-evaporated organic light emitting diodes[J]. ACS Applied Materials & Interfaces, 2016, 8(14): 9268–9274. |

| [79] | Jun S. Ju B K, Kim J W. Fabrication of substrate-free double-side emitting flexible device based on silver nanowire-polymer composite electrode[J]. Current Applied Physics, 2017, 17(1): 6–10. DOI:10.1016/j.cap.2016.10.016 |

| [80] | Kang H, Kang I, Han J, Kim J B, Lee D Y, Cho S M, Cho J H. Flexible and mechanically robust organic light-emitting diodes based on photopatternable silver nanowire electrodes[J]. The Journal of Physical Chemistry C, 2016, 120(38): 22012–22018. DOI:10.1021/acs.jpcc.6b06599 |

| [81] | Jung E, Kim C, Kim M, Chae H, Cho J H, Cho S M. Roll-to-roll preparation of silver-nanowire transparent electrode and its application to large-area organic light-emitting diodes[J]. Organic Electronics, 2017, 41: 190–197. DOI:10.1016/j.orgel.2016.11.003 |

| [82] | Ye T, Jun L, Kun L, Hu W, Ping C, Duan Y H, Zheng C, Liu Y F, Wang H R, Yu D. Inkjet-printed Ag grid combined with Ag nanowires to form a transparent hybrid electrode for organic electronics[J]. Organic Electronics, 2017, 41: 179–185. DOI:10.1016/j.orgel.2016.10.046 |

| [83] | Lee P, Lee J, Lee H, Yeo J, Hong S, Nam K H, Lee D, Lee S S, Ko S H. Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network[J]. Advanced Materials, 2012, 24(25): 3326–3332. DOI:10.1002/adma.v24.25 |

| [84] | Gaynor W, Hofmann S, Christoforo M G, Sachse C, Mehra S, Salleo A, McGehee M D, Gather M C, Lüssem B, Müller-Meskamp L, Peumans P, Leo K. Color in the corners:ITO-free white OLEDs with angular color stability[J]. Advanced Materials, 2013, 25(29): 4006–4013. DOI:10.1002/adma.v25.29 |